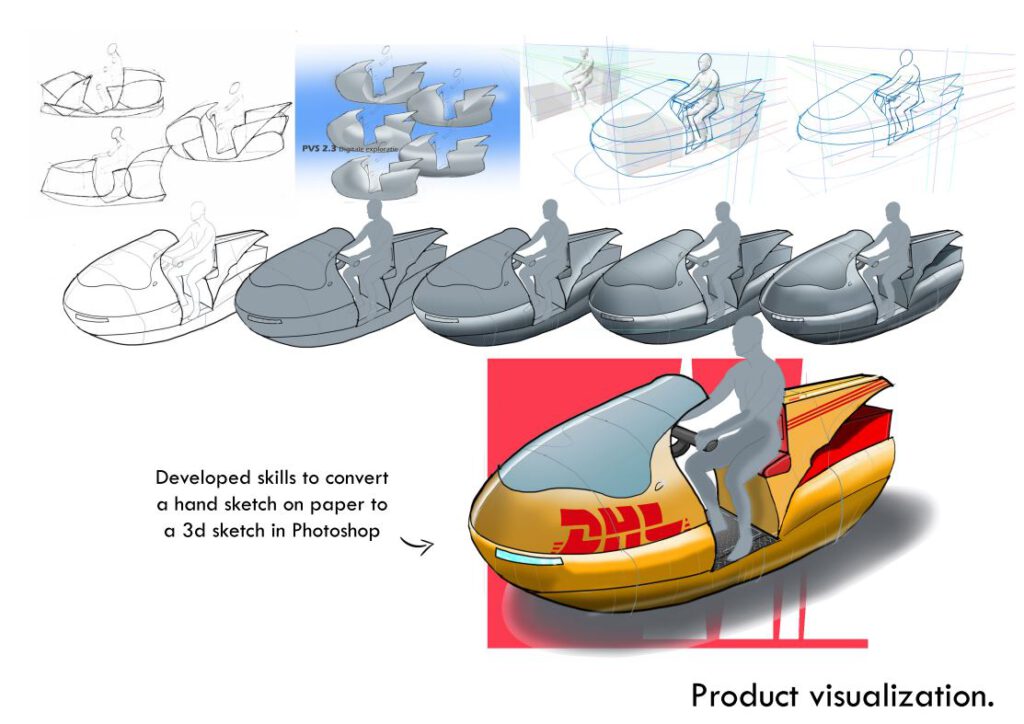

In 2019 I completed the bachelor’s program in Industrial Product Engineering at The Hague University of Applied Sciences. My bachelor’s degree was focused on learning a traditional and linear product design process. I was trained as an industrial designer to develop innovative products from idea/concept to deployment. All the different design phases were addressed separately based on projects and associated subjects. I gained knowledge of traditional product design, drawing in Solidworks (CAD), production processes & materials, product visualization, construction, and ergonomics.

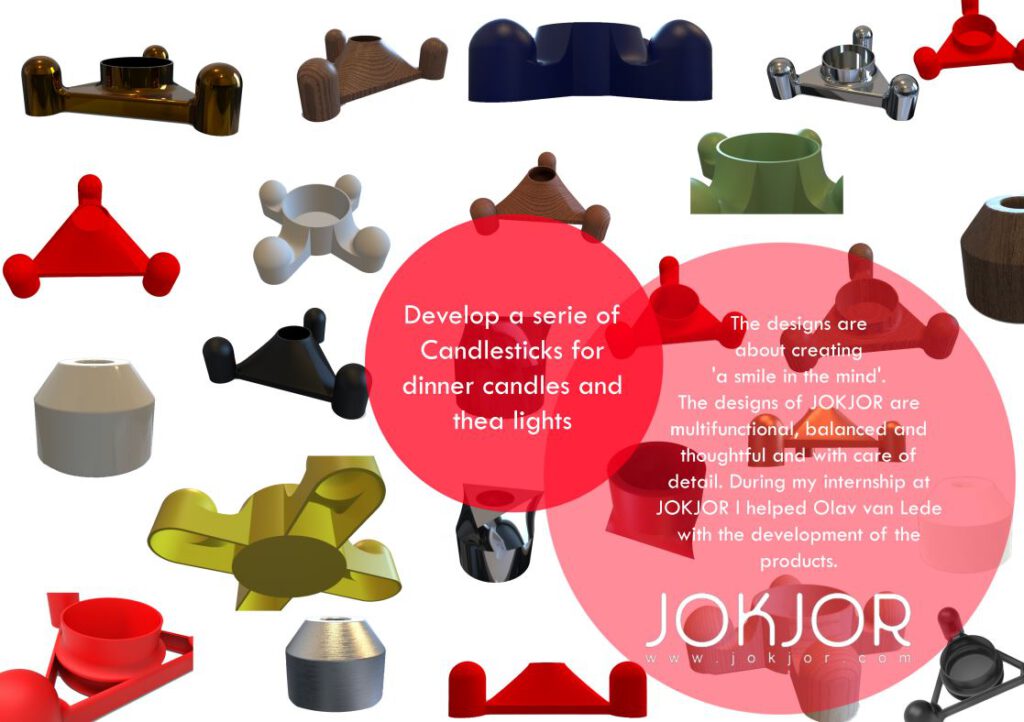

I did my first internship at JOKJOR, where they designed interior and exterior furniture and accessories. I enjoyed this experience as a product designer and the assistant of the brand owner. He gave me much freedom, which allowed me to be more creative. The owner also taught me how the distribution of your brand works. However, I learned I am interested in designing more technically advanced products.

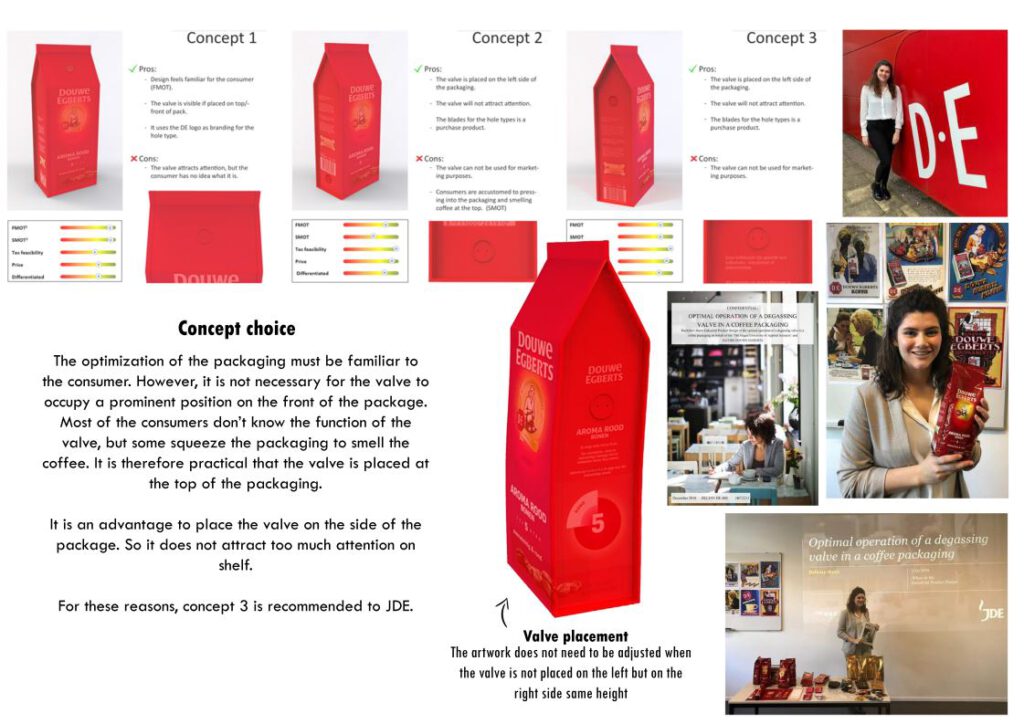

My graduation internship was at the Research and Development department of JACOBS DOUWE EGBERTS (JDE). Here I did experiments inside the plant. I graduated on the ”Optimal operation of a degassing valve in a coffee packaging”. I liked the energetic, inquisitive environment of the R&D packaging team of JDE. This sparked an interest in the field and approach of work that I am currently pursuing.

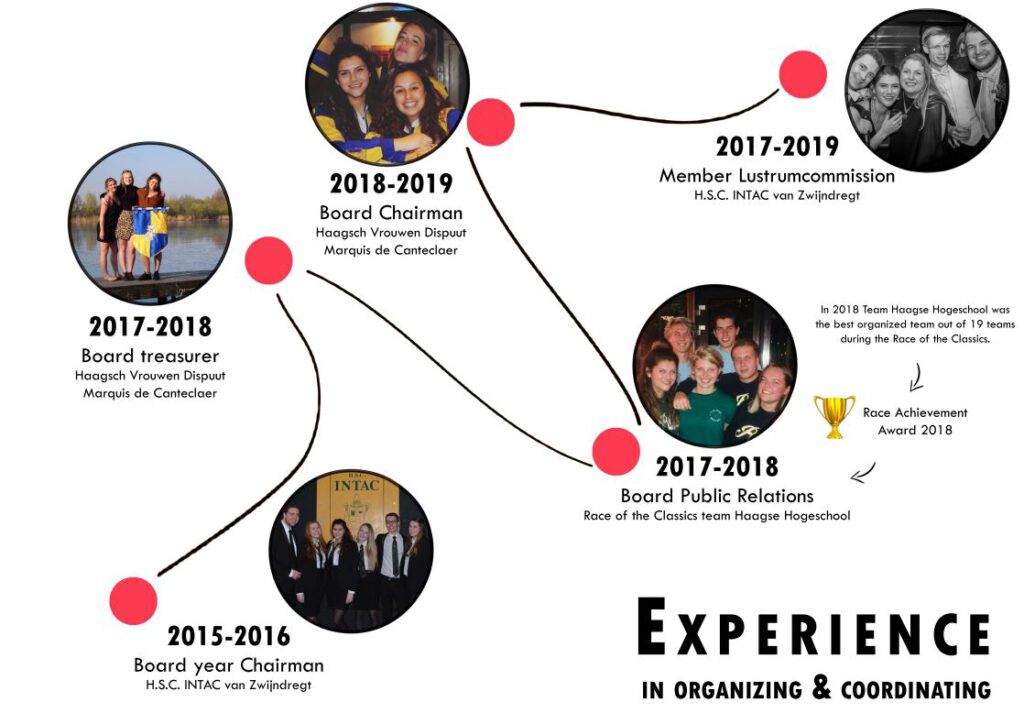

In addition to my undergraduate degree, I did many extracurricular activities. As a result, I learned that I enjoy organizing events, coordinating committees, and managing clubs. The experiences within boards and committees provided managing projects and stakeholders within my food projects. Furthermore, from age 16 to 21, I worked in various restaurants. My experiences as a waitress helped with the restaurant perspective and empathized with the user and were valuable for Inclusive Gastronomy design.

After graduating in February 2019, I explored options to start working or further my academic career. In August 2019, I began working full-time as a Packaging Coordinator at ASML. I liked working in such a large company and learned much from my colleagues. I was working on special packaging for a new microchip machine. For this, I had to talk to the different disciplines that made components for the machine, and with this, I collected the specifications needed for the unique packaging. This way, I ensured that the designer had the correct information to start designing the packaging. I also got the chance to participate in developing a large package. Although I liked to work with all these specialized colleagues, the designer in me needed to be more stimulated. I also wanted to continue learning and broaden my knowledge, and I enrolled in the transition year for the master’s program of Industrial Design at the TU/e. I worked another year at ASML for 16 hours a week besides my studies but later decided to focus entirely on my master’s degree.